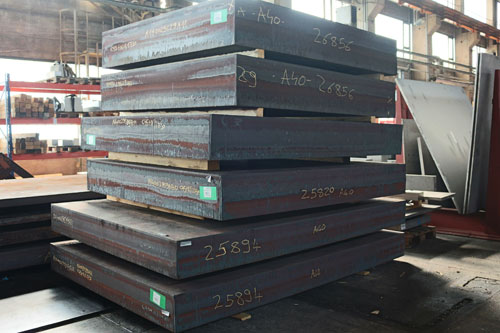

1.0503 (C45) | 1.1730 (C45U) directly from stock & cut to your required dimensions!

C45 is a non-alloyed steel. Parts of the engineering and automotive industries or even hand crafted tools and building panels are made of it.

C45 is difficult to weld and is not suitable for welded structures. Upon cooling after welding easy stress cracks may occur if the cooling does not happen under controlled conditions.

| 1.0503 C45 1.1730 C45U | C | Si | Mn | P | S | Cr | Mo | Ni | V |

|---|---|---|---|---|---|---|---|---|---|

| C45 min. C45U min. | 0,42 0,42 | 0,15 | 0,5 0,6 | ||||||

| C45 max. C45U max. | 0,5 0,5 | 0,4 0,4 | 0,8 0,8 | 0,045 0,03 | 0,045 0,03 | 0,4 | 0,1 | 0,4 |

| 1.0503 C45 1.1730 C45U | Al | Cu | N | Nb | Ti | Sonstiges |

|---|---|---|---|---|---|---|

| C45 min. C45U min. | ||||||

| C45 max. C45U max. | Cr+Mo+Ni max. 0,63 |

plates, rolled / forged, annealed / normalized

The processing with the saw is a mechanical processing of the material, which results in a significantly lower unintended deformation and increased hardness for the existing structure, such as the thermal cutting.

Thus, the machined workpiece has a homogeneous structure even at the edge, which does not change in the continuation of the material.

This circumstance allows immediate finishing of the workpiece with milling or drilling . So it is not necessary to anneal the material or make a similar operation beforehand.

Do you have any questions?

We are happy to answer your questions and make you an offer for these and other materials. Contact us now for more information.

Your contact person Andreas Blachowiak+49 (0) 35263-665-37blachowiak@stahlportal.com

Notice: Specifications contained in following data sheet are provided as a description, liability is excluded!